Spray Dryer Manufacturers in Pune Suppliers, Dealers in Pune

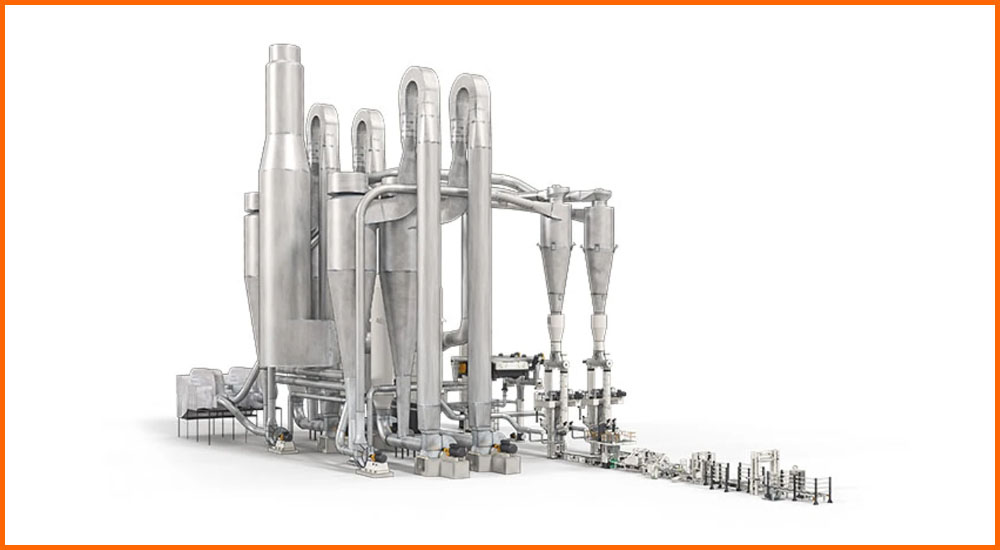

Spray Dryer Manufacturers in Pune High-Efficiency Spray Dryer Pune, Mini Spray Dryers, Custom Spray Dryer Manufacturers in Pune

We are the trusted Spray Dryer Manufacturers in Pune suppliers in Pune. We provide a diverse range of spray dryers in Pune, including standard stainless steel pilot spray dryers with capacities. Oue team of experts can also customize spray dryers to cater to specific applications, such as protein powder spray dryers and herbal extracts spray dryers.

Why Choose Hindustan Process Systems?

Hindustan Process Systems is committed to delivering products of the highest quality. Their spray dryers are engineered with precision and undergo stringent quality control checks to ensure optimal performance. The company has a highly skilled team of engineers and technicians with years of experience in designing, manufacturing, and servicing spray drying systems.Hindustan Process Systems uses the latest technology and innovative approaches to design spray dryers that offer efficiency, reliability, and high-quality output.

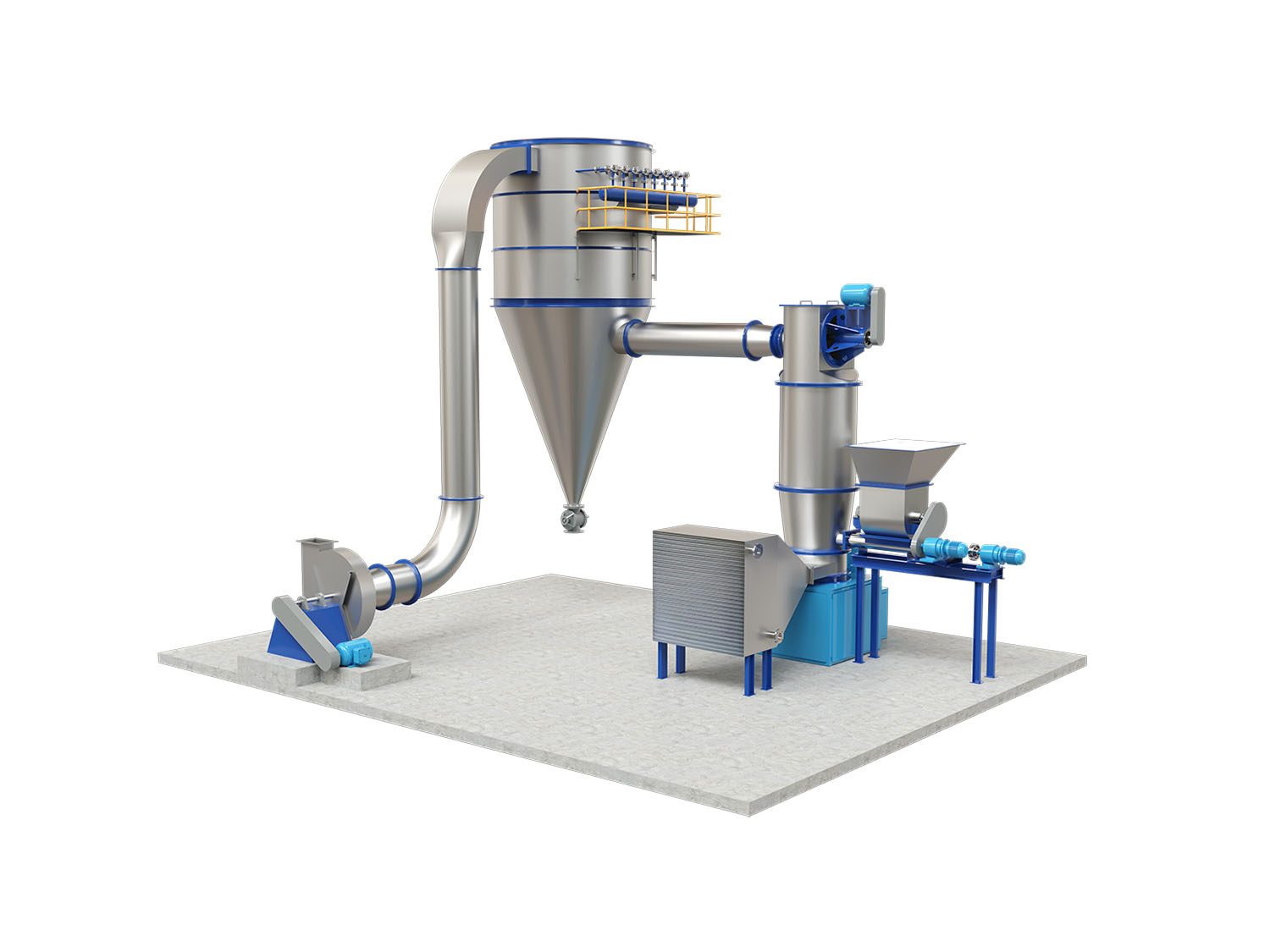

A spray dryer is a device used to convert liquid substances into powder form through the process of rapid drying. This technology is commonly employed in industries like food processing, pharmaceuticals, chemicals, and biotechnology. The primary purpose of a spray dryer is to produce fine, dry powders from a liquid feed, making it ideal for products that require powder form, such as powdered milk, instant coffee, detergents, and pharmaceuticals.

How Does a Spray Dryer Work?

- Atomization: The liquid feed (which can be a solution, suspension, or slurry) is pumped into the spray dryer. A high-speed rotating atomizer or nozzle then disperses the liquid into tiny droplets. This atomization process creates a large surface area for efficient drying.

- Drying: The droplets are introduced into a hot air chamber. The air is typically heated to temperatures between 150°C to 300°C, depending on the material being dried. As the droplets fall through the chamber, the moisture evaporates rapidly, leaving solid particles behind.

- Collection: The dried particles, now in powder form, are collected at the bottom of the chamber or via a cyclone separator. The dried powder is then further processed and packaged for use or sale.

With vast experience and expertise in Spray Dryer manufacturing, we ensure optimal performance and efficiency in your drying processes. We known for the high-quality spray dryers with their cutting-edge technology and excellent after-sales service, We have successfully completed numerous projects in the industry.

Hindustan Process Systems, a platform where you can find a variety of mini spray dryers. We offer compact and efficient solutions to meet your research and development needs.

Being a top Spray Dryer Manufacturers in Pune, our spray dryers are securely constructed and have configurable setups that allow for flexibility and scalability to meet the specific needs of each application. Our systems are designed to produce reliable results even in the most demanding conditions, whether they are being used for batch processing or continuous operation.

Advantages:

- Improved Product Quality: As leading Spray Dryer Manufacturers in Pune Suppliers, Exporters in Pune, our spray dryers generate consistently high-quality products with a consistent particle size distribution and less agglomeration. Our solutions provide accurate control over product properties and uniform drying for powders, granules, and microencapsulated materials.

- Cost Efficiency: Our spray dryers assist lower production costs and increase profitability by streamlining the drying process and minimizing waste. Businesses can gain substantial savings over time by increasing their efficiency and consuming less energy, which will strengthen their competitive advantage in the marketplace.

- Streamlined Operations: Being Spray Dryer consultant, our spray dryers save downtime and streamline operations since they are made to be easy to use and maintain. Our solutions guarantee continuous production and flawless workflow integration with their user-friendly controls and convenient cleaning and service accessibility.

Categories :

- Pressure Nozzle Spray Dryers: These high-efficiency, uniform drying devices are perfect for situations where fine control over particle size and morphology is required. These systems are excellent at creating tiny powders and granules with reliable qualities because of their customizable nozzle configurations.

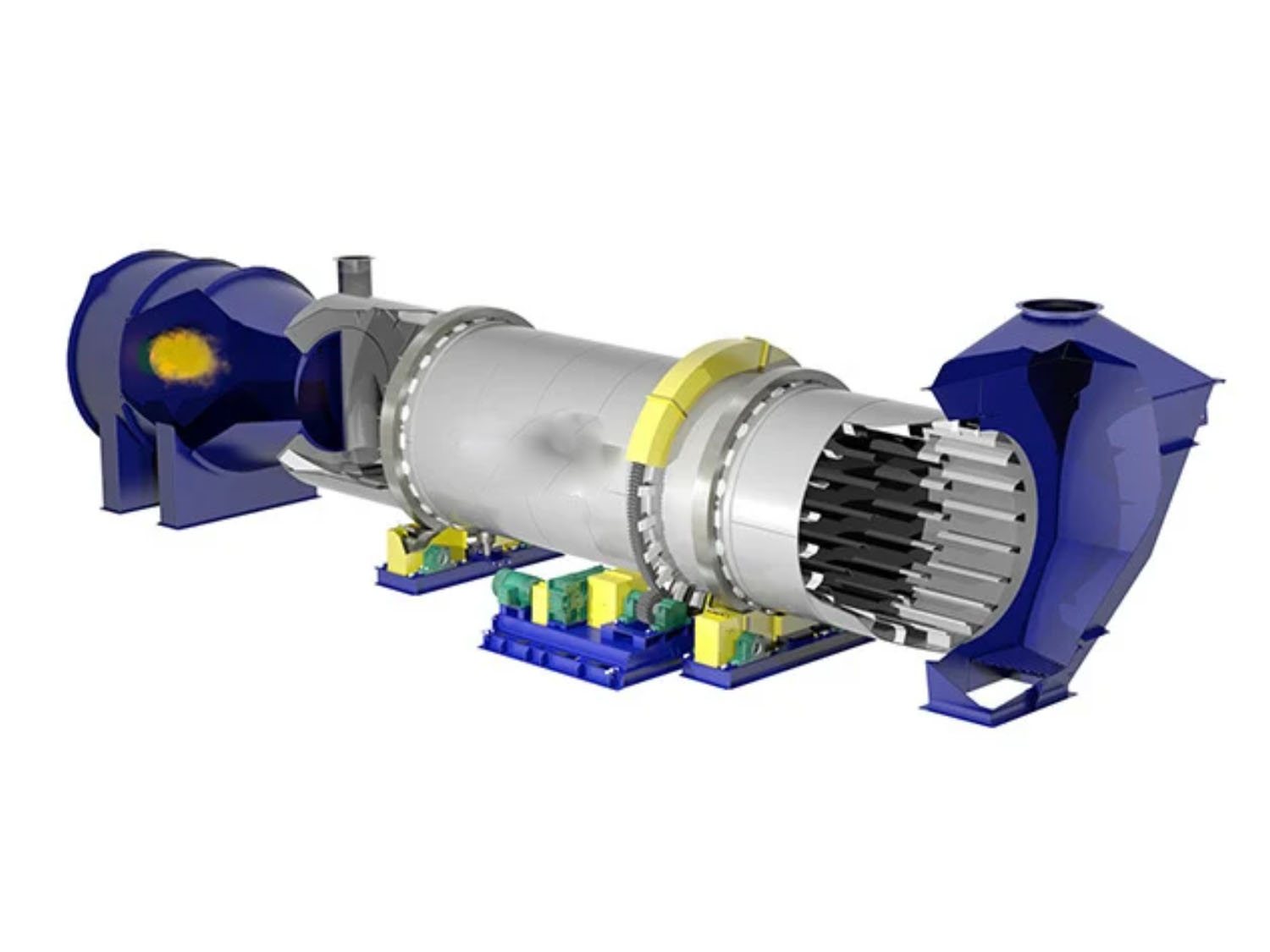

- Rotating Atomizer Spray Dryers : These dryers are renowned for their adaptability and scalability, and they may be used with a variety of materials, including heat-sensitive chemicals and viscous slurries. These systems create homogeneous droplets for effective drying and minimal product deterioration by atomizing liquids with centrifugal force.

- Fluid Bed Spray Dryers: Perfect for applications needing agglomeration and particle size control, fluid bed spray dryers combine drying and granulation in one step. The pharmaceutical, food, and chemical sectors can benefit from these systems since they provide improved product homogeneity and decreased dust production thanks to fluidization technology.

Applications

- Pharmaceuticals: Our spray dryers provide accurate control and gentle processing for pharmaceutical applications, ranging from medication formulation to the manufacturing of excipients and APIs. Whether manufacturing controlled-release formulations or inhalable powders, our methods guarantee regulatory compliance and stable product quality.Spray Dryer Manufacturers, Suppliers, Exporters in Pune

- Food Processing: Our spray dryers serve the food processing sector with effective and hygienic drying solutions, whether they are used for instant coffee, powdered flavors, or nutritional supplements. Our technologies maintain the nutritional value and sensory qualities of food ingredients by gently processing them and offering customizable combinations.

- Chemical Manufacturing: Because of our spray dryers' dependability and adaptability, chemical manufacturers all over the world rely on them for anything from specialty chemicals to catalysts and polymers. Our systems provide reliable results for a variety of chemical applications, whether they are creating fine powders or granules with exact requirements.

When it comes to industrial drying technology, Hindustan Process Systems, are the pinnacle of innovation and dependability. Our solutions provide businesses with unparalleled performance, accurate control, and flexible applications, enabling them to attain unprecedented levels of efficiency and production. With our advanced spray dryer systems, you can feel the difference and advance your manufacturing procedures.

Frequently Asked Questions about Spray Dryer :

Q: What is the principle of operation for spray dryers? Spray dryers function by drying a liquid and collecting the resulting powder without any intermediate manual handling. The liquid is atomized using a rotating wheel or a nozzle, and the spray of droplets comes into contact with a flow of hot drying medium, usually air. Correct atomization and air distribution are crucial for the quality and structure of the final powder. Spray dryers are available in various capacities and can be equipped with different atomizersQ: What are the different types of atomizers used in spray dryers? Spray dryers use various types of atomizers to disperse the liquid or slurry into a controlled drop size spray. The most common atomizers are rotary disk and single-fluid high-pressure swirl nozzles. Rotary atomizers provide a broader particle size distribution, while high-pressure swirl nozzles allow for consistent distribution of particle size

Q: How does a spray dryer work? In a spray dryer, a liquid input stream is sprayed into a hot vapor stream, causing the liquid to evaporate. The droplets evaporate quickly, and the resulting solids are collected in a drum or cyclone. The spray drying process is faster than other drying methods and simplifies the process by converting a solution into a dried powder in a single step

Related Searches:Spray Dryer Manufacturers in Pune, Spray Dryer Suppliers in Pune, Spray Dryer Exporters in Pune, Spray Dryer Consultant in Pune

What We Do

Our Products