Consultancy for all types of Industrial Dryers in India from Pune

Hindustan Process Systems provider of Consultancy services for all types of Industrial Dryers in India from Pune, helps businesses identify new methods to make their drying processes better. We are well aware that when it comes to the changing world of industrial manufacturing today, efficient and effective drying processes are crucial for making sure that products are of the greatest quality.

Details about the product:

Industrial dryers are key instruments in many production industries because they remove moisture from materials and products rapidly and effectively. provider of Consultancy services for all types of Industrial Dryers we look at various types of industrial dryers, like as

- Spray Dryers: Spray dryers use atomization to transform liquid feed into droplets. These droplets are subsequently dried in a stream of hot air to form powders and grains.

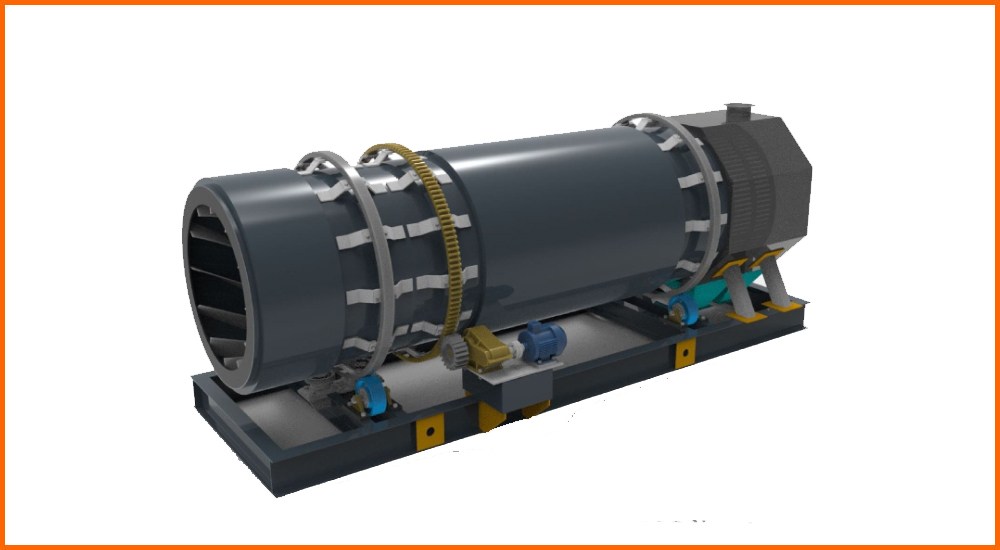

- Rotary Dryers: Rotary dryers dry things directly with hot air since their drums revolve. This makes them handy for many various types of materials and uses.

- Flash dryers: We employ high-speed hot air to swiftly evaporate dampness from materials, making them suitable for heat-sensitive objects. They are noted for how rapidly they dry stuff.

- Pneumatic Conveying Dryers: These dryers employ pneumatic systems to transport objects through a stream of hot air, drying them as they go.

- Hot Air Generators: These systems produce hot air from a number of fuels, making them a versatile heat source for industrial drying processes.

Advantages:

- Customized Solutions: As a provider of Consultancy services for all types of Industrial Dryers. Our consultancy services are focused on offering tailored solutions that match the individual demands of each customer. Whether we're refining present dryer systems or constructing new ones from scratch, we make sure our solutions fit your unique demands and goals.

- Efficiency Enhancement: By reviewing and optimizing drying processes, we help firms increase efficiency, decreasing energy usage, and lowering production costs. Our knowledge of process optimization guarantees that your drying processes function swiftly and efficiently.

- Technology Integration: We stay up with the newest advancements in drying technology and incorporate creative ideas into our consulting services. We help firms optimize their drying processes by employing cutting-edge technologies such as automation and control systems, as well as novel heat transfer technology.

Benefits:

- Improved Product Quality: Optimized drying operations improve product quality by guaranteeing uniform moisture content and retaining product integrity. Whether it's food, pharmaceuticals, chemicals, or other items, our consulting services help to assure uniformity and quality throughout the drying process.

- Cost Savings: By optimizing drying operations and minimizing energy usage, our consultancy services assist organizations decrease operational expenses and increase total profitability. Our familiarity with efficiency enhancement ensures that you get the most out of your drying systems while minimizing waste and downtime.

- Compliance and Safety: We being the leading provider of Consultancy services for all types of Industrial Dryers, stress adherence to industry regulations and safety requirements in all of our consultancy services. By conducting thorough assessments and adopting best practices, we support organizations in meeting regulatory obligations and ensuring safe working conditions for their employees.

Types:

Our consulting services include a wide range of industrial dryers, including:

Spray dryers are useful for sectors such as food processing, pharmaceuticals, and chemicals, as they provide efficient and diversified methods for generating powders and granules from liquid feedstock.

Rotary dryers are commonly utilized in fields such as mining, agriculture, and construction. They provide consistent and cost-effective drying options for a wide range of commodities, including minerals, ores, and agricultural items.

Flash dryers: Flash dryers are used in areas such as ceramics, polymers, and environmental remediation to dry heat-sensitive materials fast.