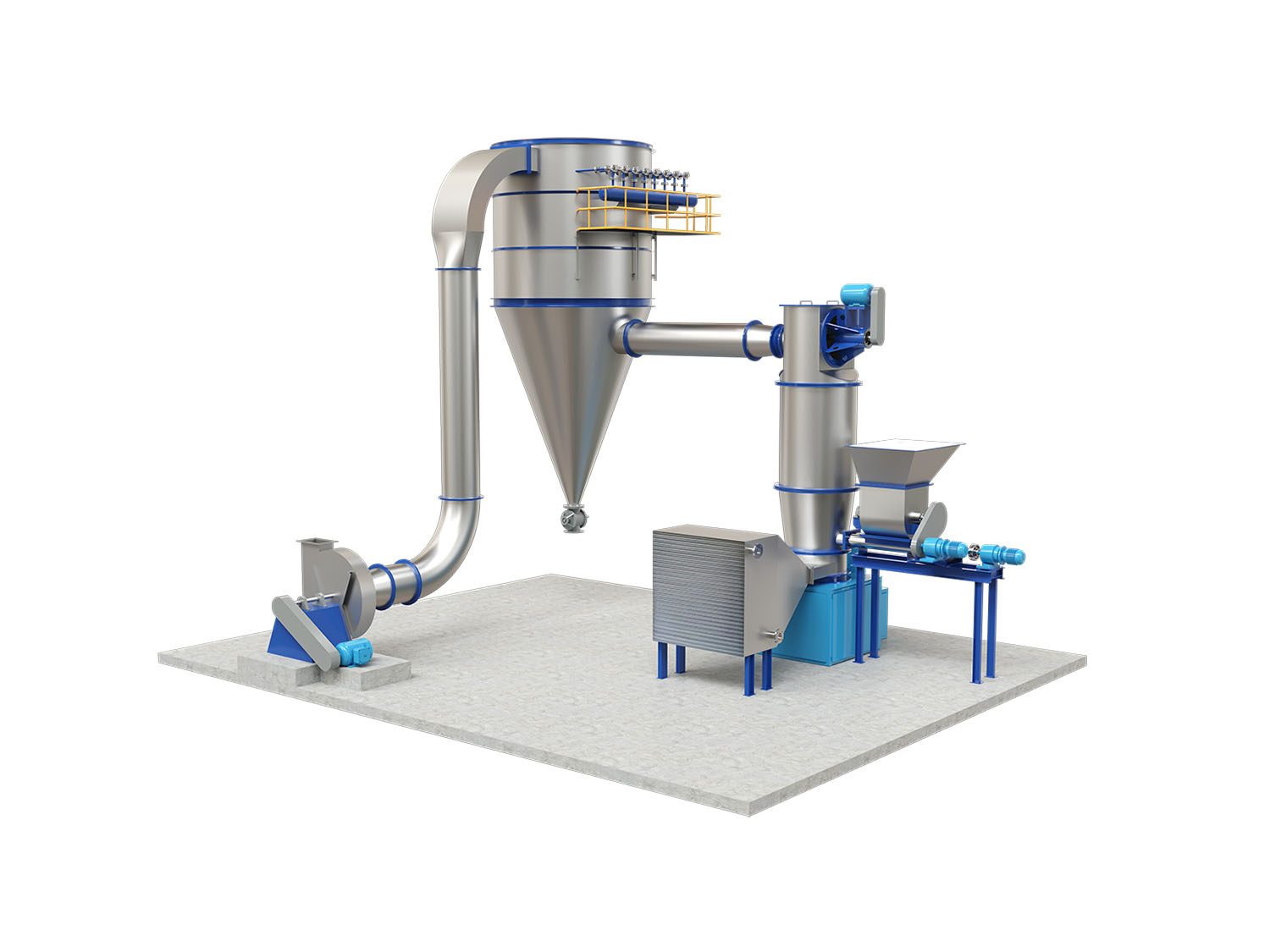

Flash Dryer Manufacturers in India

We are the leading Flash Dryer Manufacturers, Suppliers in India from Pune Maharashtra. where efficiency and innovation combine to revolutionize the drying process.we take pride in providing top-notch solutions that cater to a wide range of industries and applications.

We are Manufacturers, Suppliers of Flash Dryers includes Regular, Disintegrated and Cage Mill type Flash dryers for various applications. Our setup is situated in Pune, Maharashtra, India.

Product Advantages :

- Rapid Drying: As leading flash dryer manufacturers in India, our flash dryers use high-velocity hot air to quickly evaporate moisture from the feed material, resulting in fast and effective drying. Our systems reduce heat exposure and energy consumption by attaining high evaporation rates and short residence durations, resulting in significant cost savings and greater production.

- Versatility and Flexibility: From tiny powders to sticky slurries and heat-sensitive materials, our flash dryers can handle a wide variety of feedstocks with different qualities. With flexible designs and versatile setups, our systems thrive in various industries, delivering solutions to even the most difficult drying challenges.

- Delicate Handling:Our flash dryers provide delicate handling and exact control of drying settings. With configurable airflow and temperature settings, our systems provide uniform drying while maintaining the end product's integrity and quality.

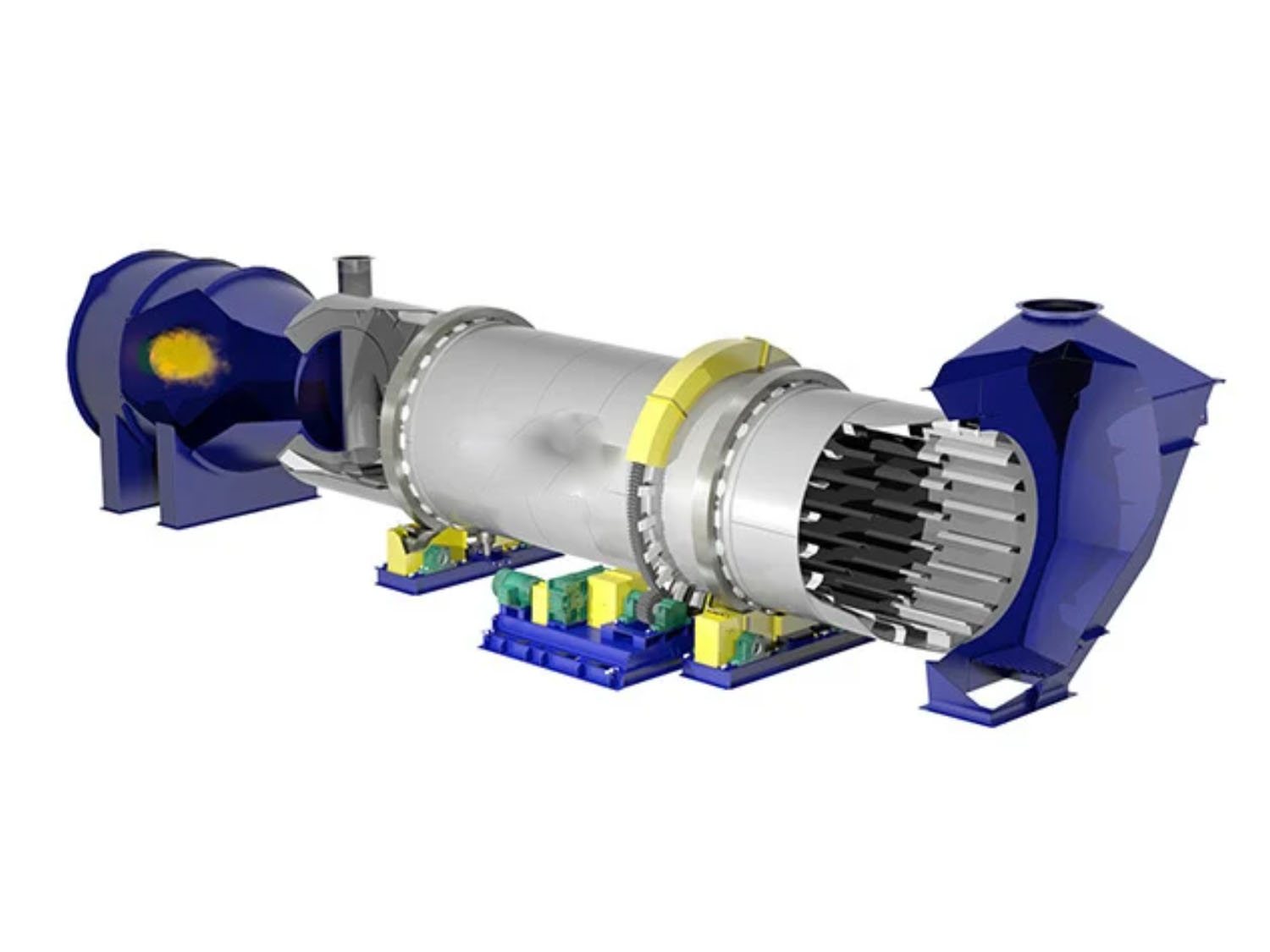

Key Working Principles of Flash Dryers:

Benefits:

- Product Quality: As leading flash dryer manufacturers in India, our flash dryers produce goods with homogeneous particle size distribution and little agglomeration, resulting in higher quality and consistency.Whether it's powders, granules, or agglomerates, our systems enable consistent drying and exact control over product properties, increasing the overall quality and value of the finished product.

- Cost Efficiency: By optimizing the drying process and limiting energy usage, our flash dryers help to lower production costs and increase profitability. With their high efficiency and rapid drying capabilities, our systems allow businesses to save considerable amounts of time, energy, and resources, giving them a competitive advantage in the marketplace.

- Improved Process Control: With powerful control systems and monitoring tools, being a flash dryer consultant our flash dryers provide unmatched process control and optimization capabilities. From altering airflow and temperature settings to monitoring moisture levels and product quality, our systems allow operators to fine-tune the drying process for maximum performance and efficiency.

Applications:

- Chemical Processing: From drying catalysts and pigments to generating specialty chemicals and intermediates, flash dryers are widely used in the chemical processing sector to dry a variety of materials efficiently and cost effectively.

- Food and Beverage: In the food and beverage business, flash dryers are used to dry food ingredients including starches, proteins, and flavors, as well as to make quick powders and beverages.

- Pharmaceutical: production uses flash dryers to dry active pharmaceutical ingredients (APIs), excipients, and drug formulations, delivering rapid and consistent drying while retaining product integrity.

- Environmental Remediation: Flash dryers are also used in environmental remediation applications to dry sludges, biosolids, and other waste materials, allowing for more ecologically friendly disposal or reuse.

Flash Dryer Manufacturers, Suppliers in India - Hindustan Process Systems

Cutting-edge Technology: We harness the power of advanced technology to design and manufacture Flash Dryers that deliver exceptional performance. Our state-of-the-art equipment ensures efficient and precise drying, minimizing energy consumption and maximizing productivity.

Customized Solutions: We understand that each industry has unique drying requirements. That's why we offer tailor-made solutions to meet your specific needs. Whether you require a compact Flash Dryer for small-scale operations or a high-capacity system for large-scale production, we have you covered.

Superior Quality: Quality is our utmost priority. We adhere to stringent quality control measures at every stage of manufacturing to ensure that our Flash Dryers meet the highest standards. From robust construction to reliable components, our products are built to last and deliver consistent results.

Exceptional Performance: Our Flash Dryers are designed to deliver rapid and uniform drying, allowing you to achieve desired moisture levels in a short span of time. With precise temperature control and efficient air circulation, our dryers ensure optimal drying results, enhancing product quality and reducing processing time.

Energy Efficiency: We recognize the importance of energy conservation. Our Flash Dryers are engineered to minimize energy consumption without compromising on performance. By incorporating innovative features and efficient airflow systems, we help you save on operational costs while promoting sustainability.

What We Do

Our Products