Spray Dryer Manufacturers in India Spray Dryer Suppliers, Dealers in India

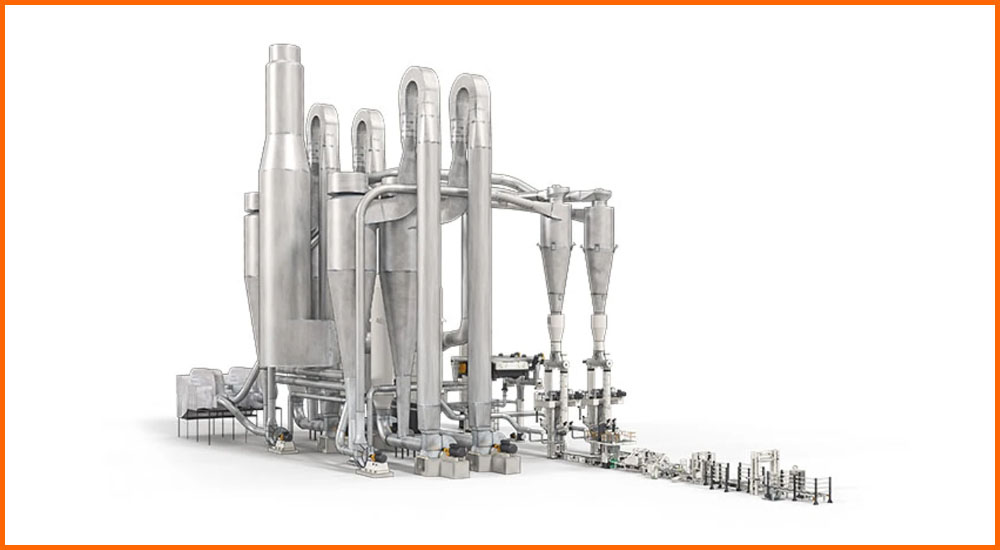

Hindustan Process System is a Premier Spray Dryer Manufacturers in India Suppliers, Dealers in India, With a commitment to innovation and excellence, we have carved a niche in the industry by providing advanced drying solutions that meet the diverse needs of our global clientele. Our spray dryers are designed with cutting-edge technology to ensure superior performance, efficiency, and reliability.

Whether it's in the food, pharmaceutical, chemical, or cosmetic industry, our spray dryers are engineered to handle various materials while preserving product integrity.

With a strong emphasis on quality and customer satisfaction, we source the finest raw materials and adhere to strict quality control measures at every stage of production. As an ISO-certified company, we follow international standards and strive to deliver products that exceed industry expectations.

What is Spray Dryer?

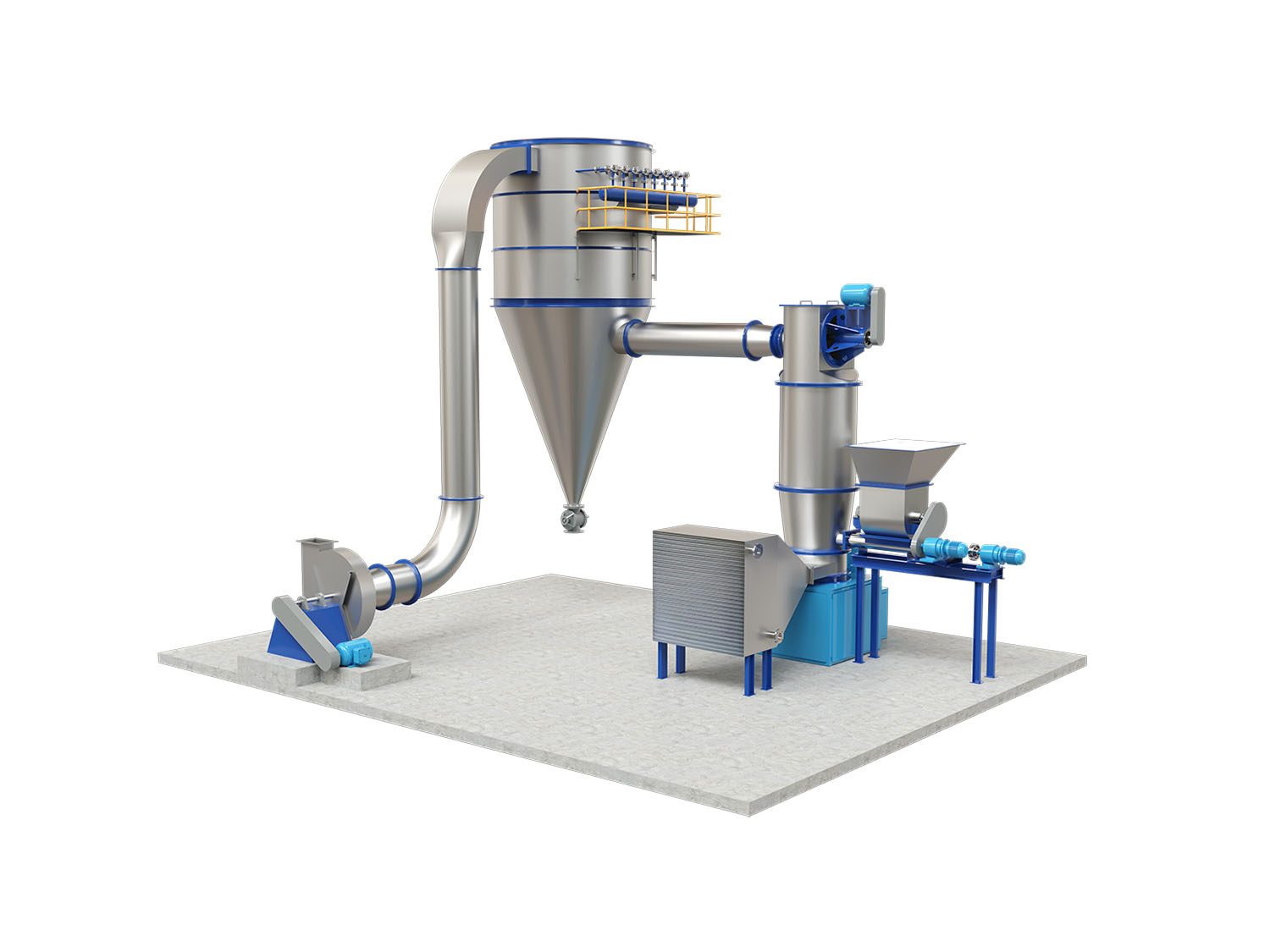

A spray dryer is a device used for converting liquid substances, such as solutions, suspensions, or emulsions, into dry powder form by rapidly drying them with hot air. This process is commonly used in industries like food, pharmaceuticals, chemicals, and cosmetics to create dry, free-flowing powders from liquid feed materials.

Types of Spray Dryer:

As Spray Dryer Manufacturers in India offering our multiple types of spray dryers, which are made with advanced features. Here we have mentioned some types below:

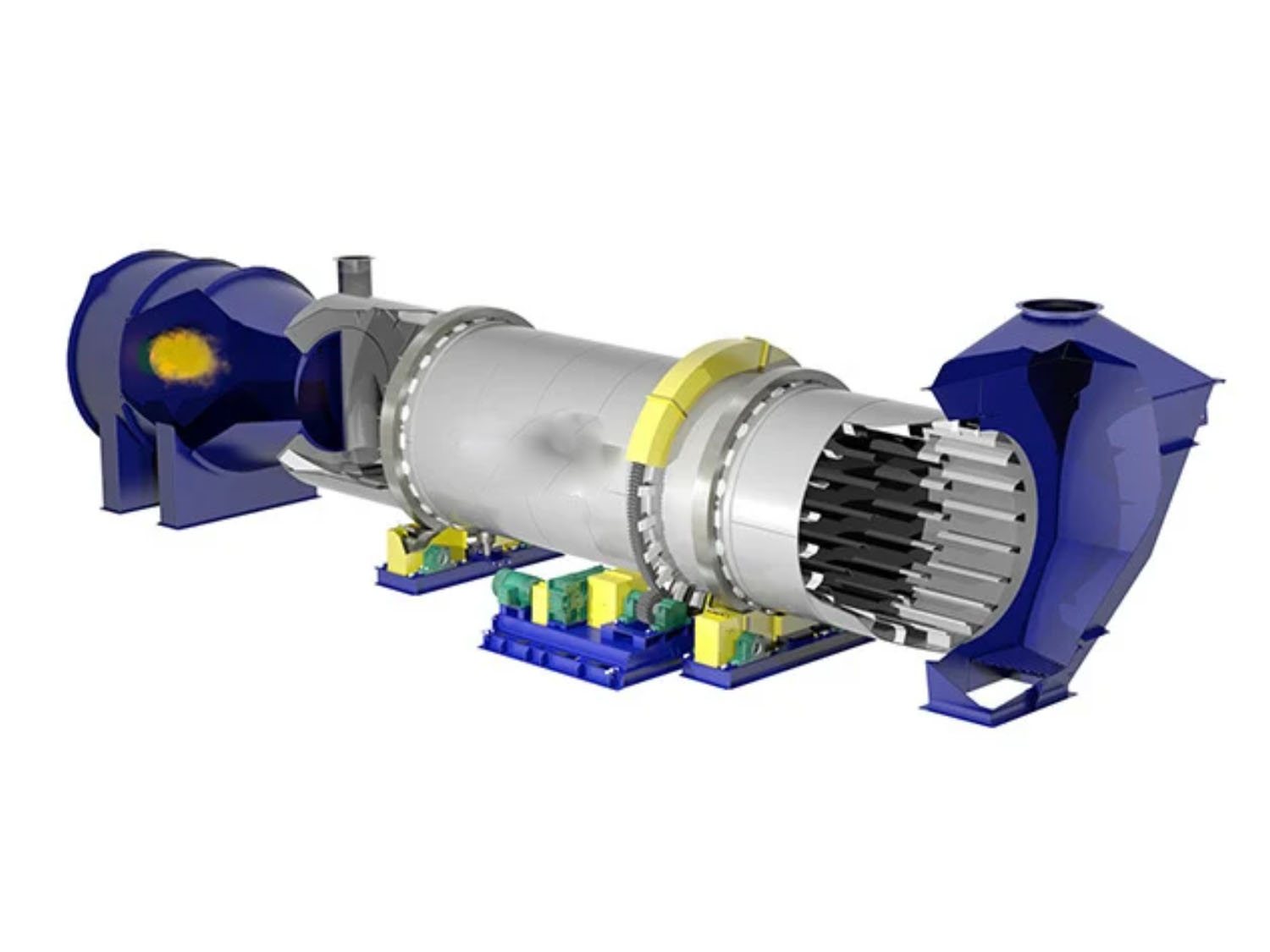

- Rotary Atomizer Spray Dryer: These Rotary Atomizer Spray Dryer manufacturers in Inida are mostly used in large-scale industries due to their higher capacity. The rotating disks and wheels are used for atomizing the feed materials and drying them quickly. These are used in the pharmaceutical and chemical industries.

- Nozzle Atomizer Spray Dryer: We Nozzle Atomizer Spray Dryer manufacturers in india. These spray dryers use specific types of nozzles, such as single or multiple, to atomize the materials and dry them quickly. These dryers have high-speed nozzles, are used in small-scale industries, and are compact.

- Fluidized Spray Dryer: We are the Fluidized Spray Dryer manufacturers in India For handling sensitive materials such as pharmaceuticals, food products, and biological materials, our fluidized spray dryers in India are mostly used due to their gentle drying process and easy-to-control structure. These are mostly used in the chemical industry.

Design of the Top Spray Dryer Manufacturers in India

The design of a spray dryer is essential in ensuring efficient and effective drying processes for various industries, such as food, pharmaceuticals, chemicals, and cosmetics. The best spray dryer manufacturers in India focus on creating advanced, customizable, and energy-efficient designs to meet the specific needs of each industry.

Key Features of the Best Spray Dryer Designs

- Atomization System: The spray dryer’s atomization system is critical in breaking the liquid feed into fine droplets. Leading manufacturers use rotary atomizers or high-pressure nozzles to create a uniform droplet size, ensuring consistent drying and optimal product quality.

- Drying Chamber: The drying chamber is designed to maximize contact between the hot air and the liquid droplets. The shape and size of the chamber are carefully engineered to optimize airflow patterns and heat transfer, ensuring quick and efficient drying.

- Airflow Control: Efficient airflow management is essential for drying efficiency. Spray dryers are designed with specific inlet and outlet air control systems, maintaining a uniform temperature and airflow throughout the chamber, which accelerates the evaporation process.

- Heat Recovery System: To enhance energy efficiency, many modern spray dryers feature heat recovery systems. These systems recapture heat from the exhaust air and use it to pre-heat the incoming air, reducing energy consumption and operational costs.

- Material Handling:Spray Dryer Manufacturers in India.Our Spray dryers are equipped with advanced systems for handling various types of materials, including viscous and sensitive products. The best manufacturers provide customized systems for product feeding, ensuring smooth processing and minimal wastage.

Advantages of Our Spray Dryers

As a leading Spray Dryer Manufacturers in India Hindustan Process System offers several key advantages:

- Versatile Plant Capacities: We provide spray dryer plants that cater to a wide range of capacities, from small-scale operations to large commercial setups.

- Consistent Powder Quality: Our systems ensure uniform powder quality throughout the drying process, maintaining the integrity of the product.

- Continuous Operation: Our spray dryers are designed for continuous operation and can be easily integrated into fully automated control systems.

- Adaptability: Our equipment is suitable for both heat-sensitive and heat-resistant products, ensuring versatility in application.

- Handling Diverse Feedstocks: Our spray dryers can process various feedstocks, including abrasive, corrosive, flammable, explosive, or toxic materials, as long as they are pumpable.

- Multiple Feed Forms: The spray drying process effectively handles feedstocks in various forms, such as solutions, slurries, pastes, gels, suspensions, or melts.

- Controlled Product Density: We can achieve desired product density as required.

Hindustan Process Systems: Expertise in Spray Drying Technology

Hindustan Process Systems is a renowned Spray Dryer Manufacturers in India suppliers, dealers of high-performance spray dryer in India, Pune. As a leading player in the industry, we have established a reputation for delivering innovative and reliable solutions to our customers across diverse sectors.

Ensuring 100% Output Efficiency

At Hindustan Process Systems, we are committed to providing our customers with the best-in-class spray drying solutions. Our spray dryer plants are engineered to deliver 100% output efficiency, addressing common challenges such as nozzle clogging, product degradation, uneven drying, and equipment fouling.

Computational Fluid Dynamics (CFD) Technology

To optimize the performance of our spray dryer systems, we leverage the power of Computational Fluid Dynamics (CFD) technology. Our in-house CFD simulations help us model and analyze the complex fluid dynamics within the drying chamber, enabling us to fine-tune the process for maximum efficiency and product quality.

Wide Range of Applications

Hindustan Process Systems' spray dryer solutions find applications across a diverse range of industries, including food and beverage processing, pharmaceuticals, chemicals, and materials manufacturing. Our versatile systems can handle liquids, slurries, pastes, gels, suspensions, and melts, transforming them into high-quality powders.

Commitment to Innovation and Customer Satisfaction

As a leading Spray Dryer Manufacturers in India, Hindustan Process Systems is committed to continuous innovation and delivering exceptional customer satisfaction. Our industry-focused approach, customer-centric mindset, and partnership-driven philosophy make us the preferred choice for businesses seeking reliable and efficient spray drying solutions.

What We Do

Our Products