Spin Flash Dryer Manufacturers in India

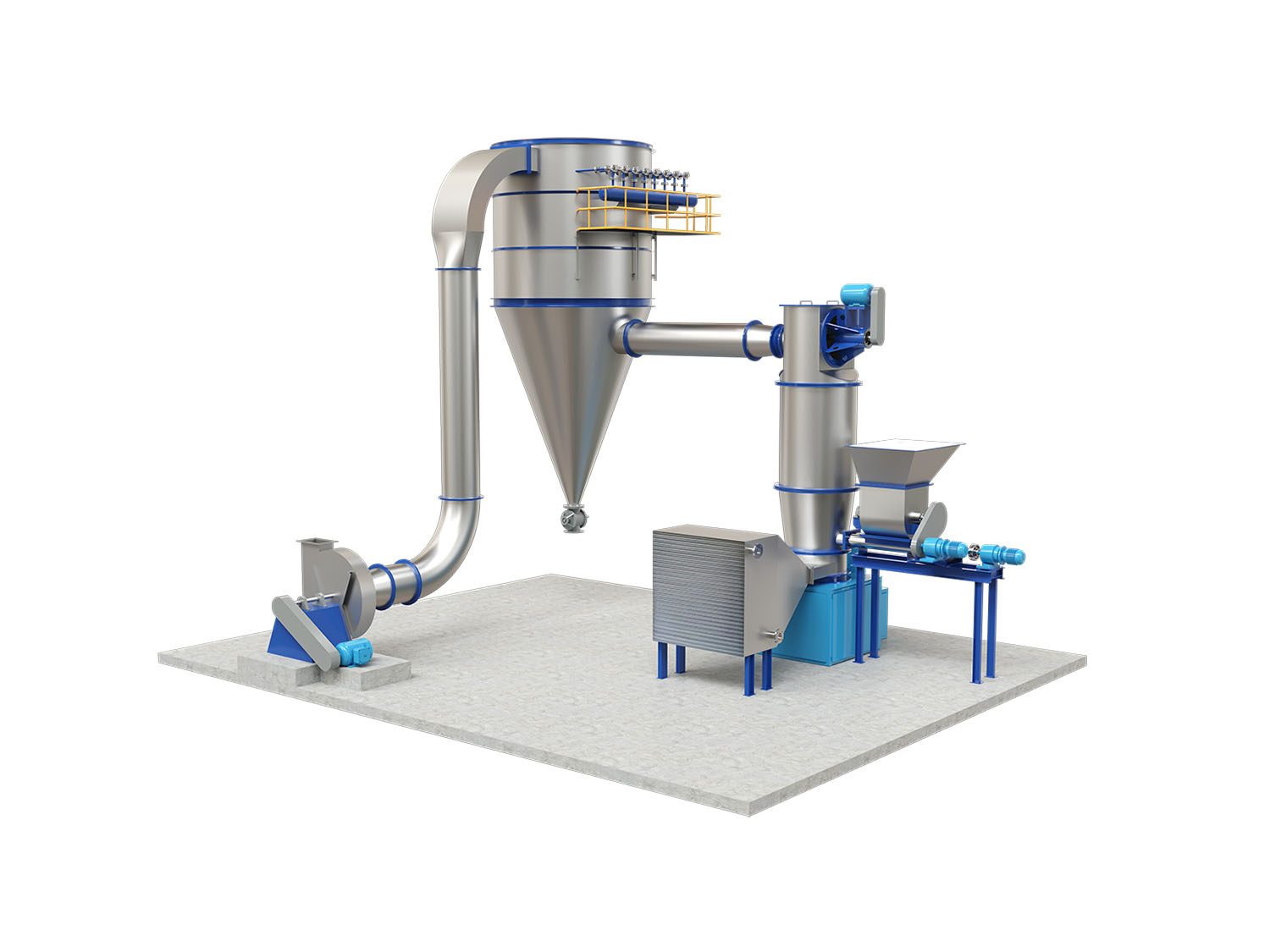

We, Hindustan Process System, the dominant Industrial Spin Flash Dryer Manufacturers, Suppliers, Exporters in India, are providing a superior quality of spin flash dryers for simplifying and improving industrial work by removing moisture from liquid and pastry materials and converting them into powdered form.

These are made with high-quality stainless steel and aluminum, which have higher durability and are applied to multiple large-scale industries. Here we have classified its multiple types, features, and application in detail:

Types of our spin flash dryer:

As a prominent spin flash dryer manufactures in India, we are offering our multiple types of dryers, such as:

- Modified Spin Flash Dryer: In these type of spin flash dryers, we have included special types of discs for handling special materials such as starch, gelatin, and polymers. It can handle sticky and heat-sensitive materials with constant material feeding and a high-speed procedure.

- Conventional Spin Flash Dryer: It has a simple, compact design and is installed with high-speed spinning discs for material dispersion. These spin flash dryers are used for drying free-flowing materials such as powder, granules, and crystals.

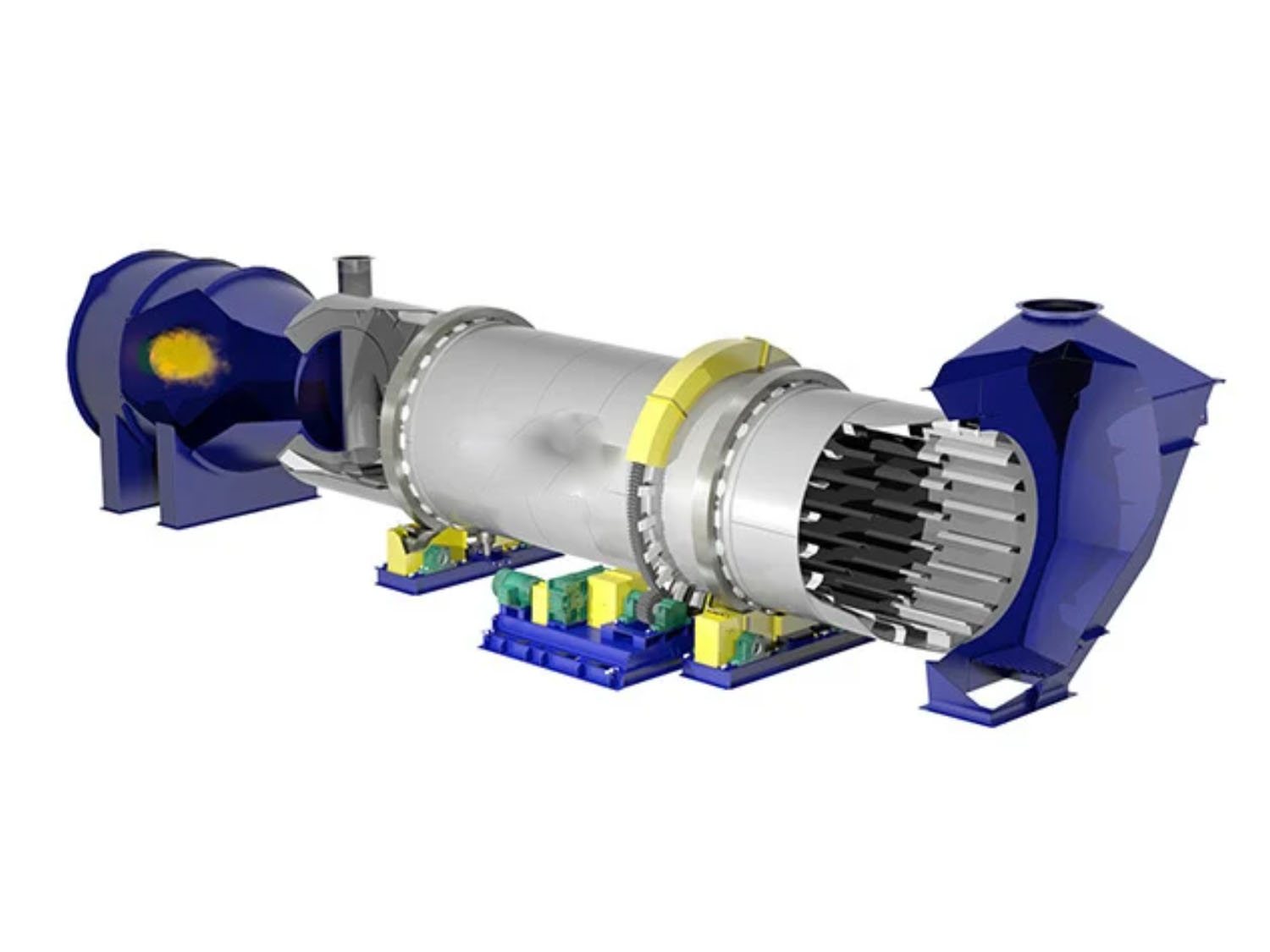

- Vibratory Spin Flash Dryer: For handling fragile and lumpy materials such as fibers, flakes, and crystals, our vibratory spin flash dryer in India is used, which combines vibration in the spinning methods to give a pure form of powder.

- Multi-Stage Spin Flash Dryer: These are our most-used Spin flash dryers, which have more flexibility compared to other dryers. It has multiple stages for drying different kinds of materials and is used in large-scale applications. These are used for drying materials such as powders, materials, and pellets.

Technical Specifications:

Being the spin flash dryer manufacturers, suppliers, exporters in India, we have provided you with a technical chart below for your guidance and in-depth details of our spin flash dryer:

| Specification | Modified Spin Flash Dryer | Conventional Spin Flash Dryer | Vibratory Spin Flash Dryer | Multi-Stage Spin Flash Dryer |

|---|---|---|---|---|

| Drying Capacity | Up to 500 kg/hr | Up to 300 kg/hr | Up to 400 kg/hr | Up to 600 kg/hr |

| Moisture Evaporation Rate | 1.5 - 2.5 kg/hr/m³ | 1 - 2 kg/hr/m³ | 1.2 - 2.2 kg/hr/m³ | 1.8 - 3 kg/hr/m³ |

| Inlet Temperature | 150°C - 300°C | 120°C - 250°C | 130°C - 270°C | 140°C - 280°C |

| Particle Size | 10-200 microns | 10-200 microns | 50-500 microns | 50-500 microns |

| Outlet Temperature | 80°C - 120°C | 70°C - 100°C | 75°C - 110°C | 80°C - 115°C |

| Drying Time | 2-5 seconds | 3-6 seconds | 2-4 seconds | 3-7 seconds |

| Feed Type | Slurry, Paste, Cake | Slurry, Paste | Slurry, Paste | Slurry, Paste, Cake |

| Feed Moisture Content | 20-80% | 15-70% | 20-75% | 25-85% |

| Final Moisture Content | 0.1-1% | 0.2-2% | 0.1-1.5% | 0.1-2% |

| Automation Level | High | Medium | High | Very High |

| Maintenance Requirements | Low, with easy access for cleaning | Moderate | Low to Moderate | Moderate to High |

| Dust Collection | Cyclone separator, Bag filter, Wet scrubber | Cyclone separator, Bag filter | Cyclone separator, Electrostatic precipitator | Cyclone separator, Bag filter, Wet scrubber, Electrostatic precipitator |

| Particle Size | 10-500 microns | 20-400 microns | 15-450 microns | 10-600 microns |

Benefits and Features of Using Our Spin-Flash Dryer

As leading spin flash dryer manufacturers, suppliers in India, all types of spin flash dryers have multiple features and benefits that give them higher performance in every task. Here we have mentioned some lists below:

- Flash Drying Technology: We have added this modern technology for rapid moisture removal in the materials and to reduce any contamination. It helps with fast drying techniques and also perverse the material properties.

- CIP (Cleaning-in-Place) System: Our all-spin flash dryers are installed with a CIP system for easy and efficient cleaning. The overall process is done with automation, so it can save time and reduce labor costs.

- High-Speed Spinning Action: These dryers have the maximum load handling capacity, and the process is done at a higher speed without any downtime. It gives a uniform moisture content and a fine result at the end.

- Dust Collection System: To reduce waste, we have added multiple types of dust collection solutions to our dryers, such as cyclone separators, bag filters, wet scrubbers, and electrostatic precipitators. This can reduce waste and dust contamination.

Applications of our spin flash dryer:

As reputed spin flash dryer manufacturers in India, all types of dryers are demanded for multiple applications, such as:

- Chemicals and Pharmaceuticals: Used for drying wet cakes, pastes, and slurries.

- Food and Beverage: These are used for drying fruit and vegetable purees and the production of breakfast cereals.

- Agrochemicals: Multiple types of pesticides and herbicide formulations are used for drying.

- Chemical Industries: Used for the production of pigment powders, dye intermediates, and final products.

- Biotechnology: These are used for drying bioproducts and biosolids.

As a leading spin flash dryer manufacturer and supplier in India, we at Hindustan Process System provide high-quality spin flash dryers that are made with durable steel and aluminum materials, which give a long-term performance without any maintenance costs.

The new in-built technological sensors and components help improve productivity and performance. Contact us today for more information about our spin flash dryer.

Our Products