Rotary Dryer Manufacturers in India - Hindustan Process System

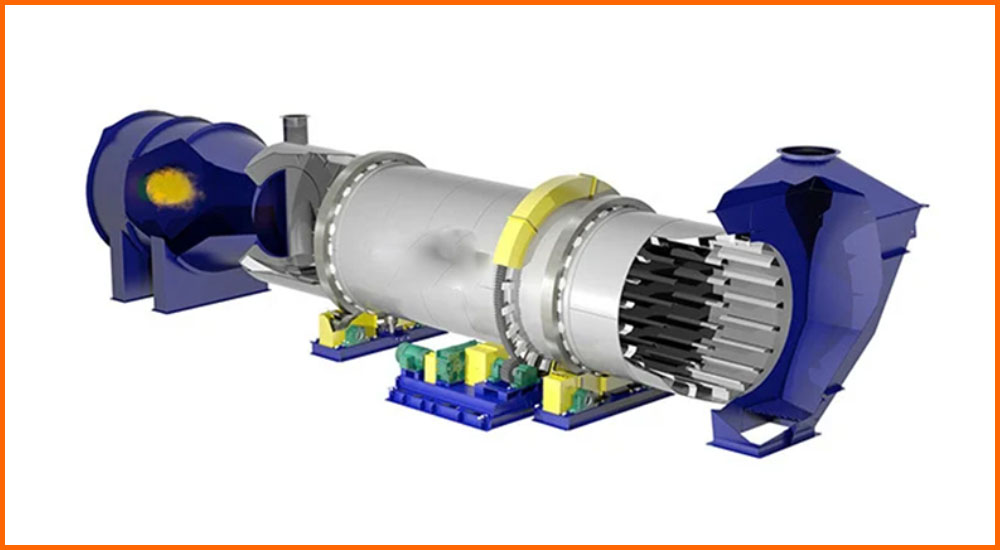

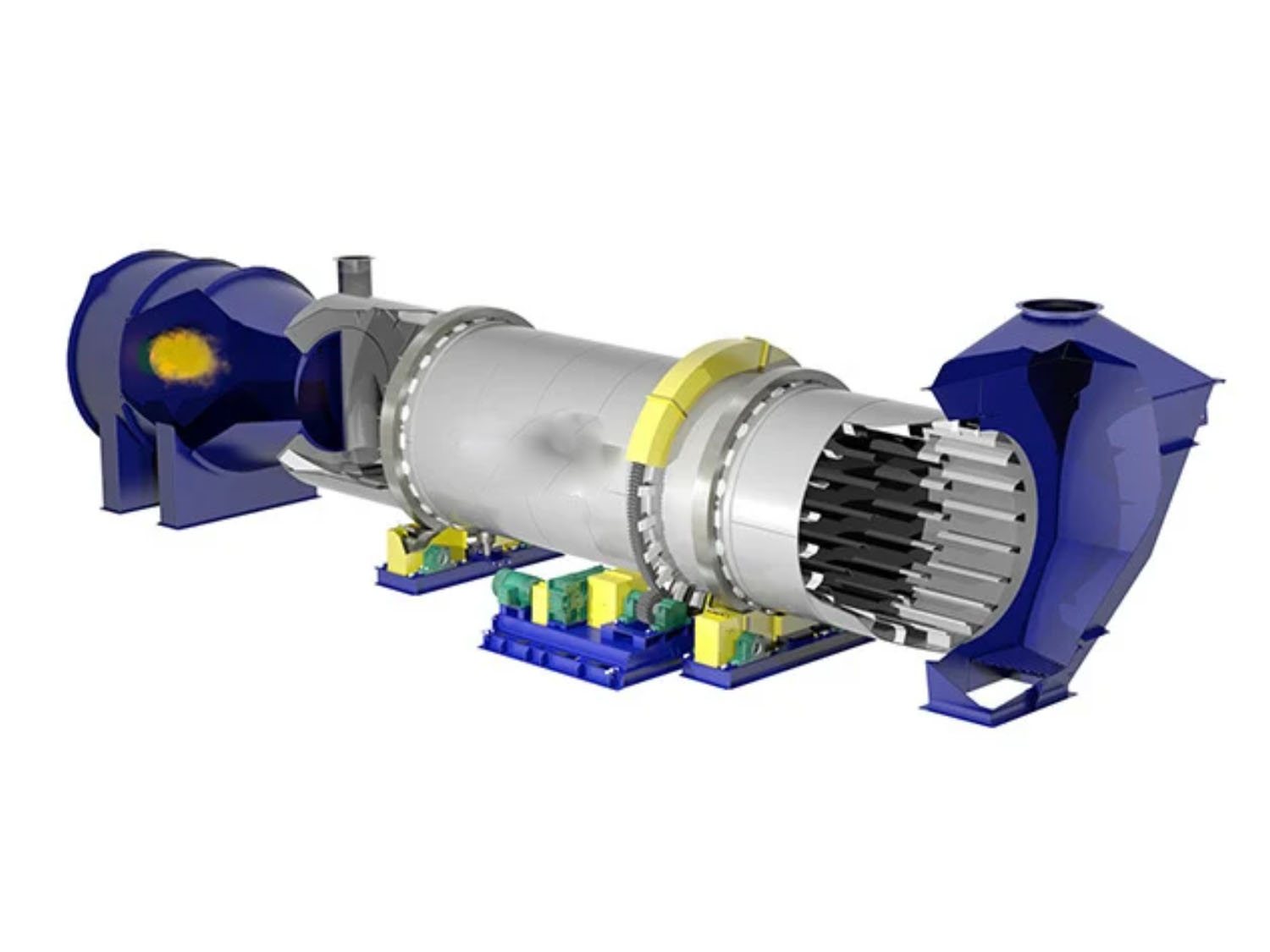

We, Hindustan Process Systems Rotary Dryer Manufacturers in India, Suppliers, Exporters in India, are offering a good quality of rotary dryers from India. that are mostly used in large-scale industries due to their high speed and pure form of moisture deduction quality with the help of heating gas.

Our Expertise - Some key areas of expertise include:

Their expertise lies in designing and manufacturing rotary dryers that cater to different sectors, including chemicals, fertilizers, minerals, food processing, and more.

- Hindustan Process System specializes in creating rotary dryers tailored to meet the specific needs of clients. Whether it's for bulk material drying or specialized processes, they offer customized designs for optimal performance.

- The company focuses on developing energy-efficient rotary dryers, minimizing operational costs while delivering maximum performance. This is achieved through innovative designs and advanced technology that optimize heat transfer and reduce energy consumption.

- Hindustan Process System integrates the latest technologies into its rotary dryers to ensure consistent quality, performance, and reduced maintenance costs. Their dryers are equipped with state-of-the-art control systems for better monitoring and management.

- Hindustan Process System offers excellent after-sales service, including installation, maintenance, and technical support, ensuring that their clients experience minimal downtime and enhanced operational efficiency.

Advantages of Rotary Dryers

One of the standout features of rotary dryers is their high efficiency in drying capabilities. They are designed to handle large volumes of material, making them particularly suitable for industrial applications where substantial quantities of product need to be dried in a short period. The design of rotary dryers allows for maximum exposure of the material to the drying air, facilitating rapid moisture removal and ensuring that the drying process is both effective and efficient.

Features of our Rotary Dryer:

Being one of the Top Qualty Rotary Dryer Manufacturers in India, Suppliers, Exporters in India, each dryer is loaded with multiple types of specifications, such as:

- Drive and Gear System: It gives a smooth and constant rotation with minimum vibration in the rotary dryer. These dryers are constructed with electric motors and gear systems with attached bearings for smooth rotation.

- Insulation and Refractory: We have added high-quality insulation materials, such as ceramic blankets and castable, to all types of rotary dryers.

- Control System: We have added advanced control systems such as HMI, thermocouples, and hydrometers for controlling the humidity.

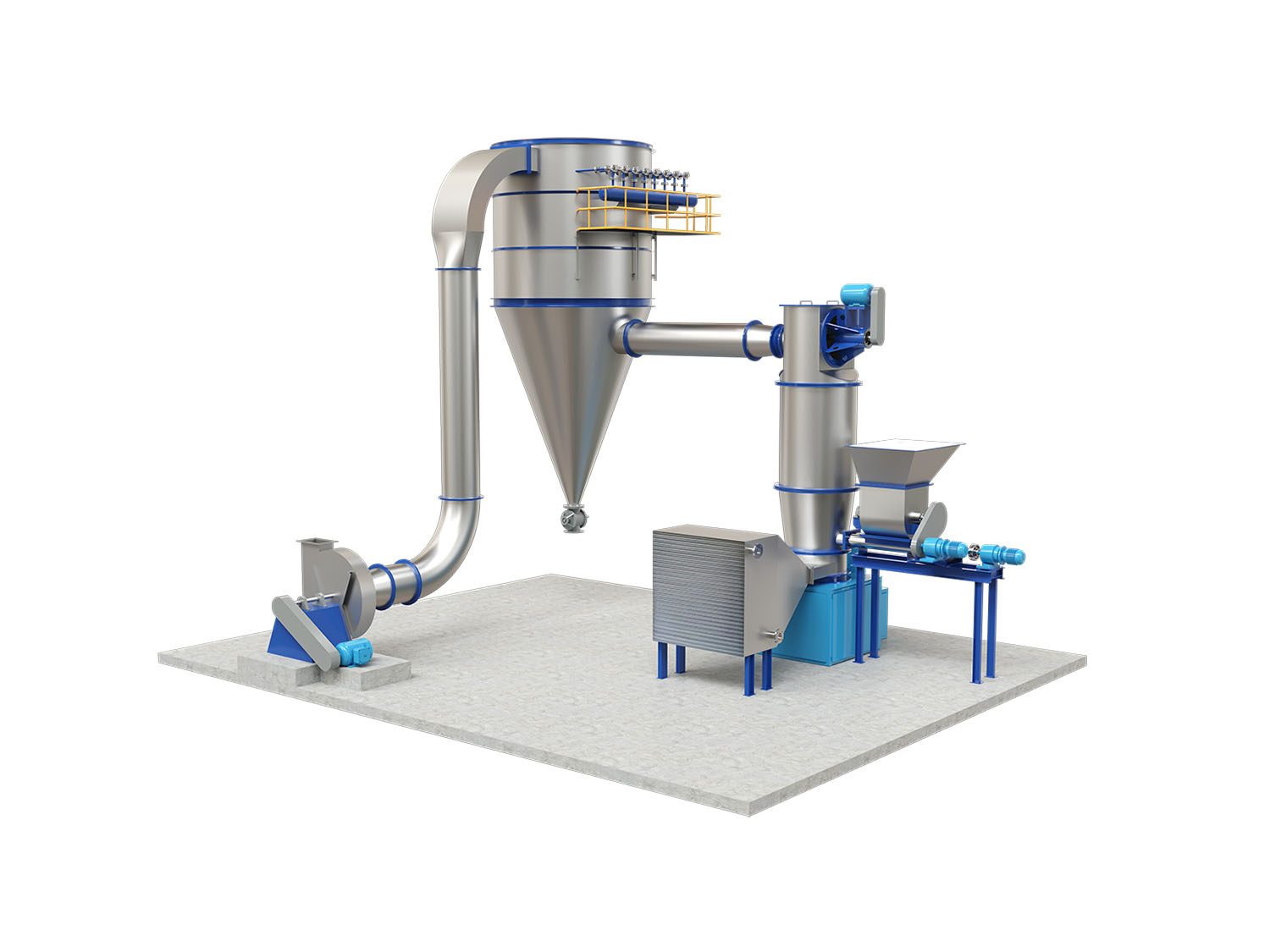

- Dust Collection System: For maintaining external contamination and reducing waste, we have attached a dust collection system to every rotary dryer system, such as cyclones, bag houses, and cartridge filters.

Specifications of Rotary Dryers

Diameter: Ranges from 1.2 meters to 4.5 meters.

Length: Varies from 6 meters to over 30 meters.

Capacity: Handles from 1 to 50 tons per hour.

Heat Source: Can be powered by gas, oil, or steam.

Material of Construction: Commonly made from carbon steel, stainless steel, and alloy steel.

Types of our Rotary Dryer:

As reputed Rotary Dryer Manufacturers in India, Suppliers, Exporters in India, we provide multiple types of rotary dryers in India, and each one is loaded with various qualities. Here we have mentioned the details below:

- Direct Rotary Dryers: For evaporating moisture, our direct rotary dryers use hot air or gas that is blown through the cylinders and applied to wet materials. It has a high drying capacity with a simple design and operation. These are used in the mineral and chemical industries.

- Indirect Rotary Dryers: These dryers use a medium for drying, such as gas, oil, or steam, and apply it to the wet materials. The materials get circulated throughout the drum, transferring heat to the material without direct contact. These dryers can handle heat-sensitive materials as well.

- Continuous Rotary Dryers: These are the high-speed dryers that work at continuous speed to increase productivity. Our continuous rotary dryers are mostly used in the food processing and chemical industries.

- Batch Rotary Dryer: For the pure extraction of powder or final result, our batch rotary dryer works in batches, such as dryer, drying, and discharge of the wet material. These are used in small-scale materials such as pharmaceuticals and chemicals.

Working Principle of Rotary Dryers

The operation involves several key steps:

- Material Feeding: Wet material is introduced into the dryer.

- Rotation: The dryer rotates, lifting and cascading the material.

- Heat Transfer: Hot air is introduced, causing moisture to evaporate.

- Moisture Removal: Moisture-laden air is expelled while dried material continues moving.

- Discharge: Dried material is collected through a discharge opening.

Applications of Rotary Dryers

Rotary dryers are widely used in:

- Mining and Minerals: Drying ores and aggregates.

- Agriculture: Drying grains, seeds, and fertilizers.

- Food Processing: Drying fruits, vegetables, and other food products.

- Chemical Industry: Drying various chemical powders.

Versatility

Rotary dryers are incredibly versatile and can be employed across a variety of industries. They are capable of drying a wide range of materials, including:

- Minerals: Such as ores and aggregates, which require efficient moisture removal to enhance their quality before processing.

- Grains: Including corn, wheat, and rice, which need to be dried to prevent spoilage and maintain quality during storage.

- Chemicals: Various chemical powders and granules can be dried effectively using rotary dryers, making them essential in the chemical industry.

Continuous Operation

Another significant advantage of rotary dryers is their ability to operate continuously. This feature allows for a steady and uninterrupted supply of dried material, which is particularly beneficial for high-demand operations. Continuous operation enhances productivity and minimizes downtime, enabling businesses to meet production targets efficiently.

Controlled Environment

The design of rotary dryers enables the creation of a controlled environment during the drying process. This ensures that products are dried uniformly and prevents overheating or damage to the material. The ability to regulate temperature and airflow helps maintain the integrity of the product, which is especially important for sensitive materials that may degrade under excessive heat.

Cost-Effective

From an economic standpoint, rotary dryers can be a cost-effective solution for many businesses. They typically exhibit low energy consumption compared to other drying methods, which translates into reduced operational costs. Additionally, rotary dryers require minimal maintenance, further lowering the total cost of ownership.

As a leading rotary dryer manufacturer in India, we are committed to delivering high-quality and efficient drying solutions tailored to our clients' specific needs. With robust designs, customizable features, and a focus on energy efficiency, our rotary dryers stand out in the market. If you are seeking efficient and effective rotary dryers for your business, we invite you to contact us today!

Technical Specifications

| Specification | Direct Rotary Dryer | Indirect Rotary Dryer | Continuous Rotary Dryer | Batch Rotary Dryer |

|---|---|---|---|---|

| Heating Method | Direct contact with hot gas | Indirect contact via metal wall | Direct or Indirect | Direct or Indirect |

| Operating Temperature Range | Up to 800°C | Up to 600°C | Up to 800°C | Up to 600°C |

| Heat Source | Natural gas, oil, coal, waste heat | Steam, thermal oil, electrical heaters | Natural gas, oil, coal, waste heat | Steam, thermal oil, electrical heaters |

| Drum Diameter | 0.5 to 5 meters | 0.5 to 5 meters | 0.5 to 5 meters | 0.5 to 3 meters |

| Drum Length | 2 to 30 meters | 2 to 30 meters | 2 to 30 meters | 1 to 10 meters |

| Efficiency | 50-75% | 60-85% | 50-75% | 60-85% |

| Emission Control | Required for direct heating | Lesser emissions due to indirect heating | Required for direct heating | Lesser emissions due to indirect heating |

| Retention Time | Adjustable from minutes to hours | Adjustable from minutes to hours | Continuous adjustment possible | Adjustable for each batch |

As a leading Rotary Dryer Manufacturers, Suppliers, Exporters in India we at Hindustan Process System are providing a modern solution for drying wet materials through our rotary dryer. These are made from high-quality materials such as cast iron and steel, which have wear-and-tear performance in the industrial sector. The new technology and advanced components help to increase productivity. Contact us today for more information!

What We Do

Our Products